Fiber: Priority for Analysis

Good diet formulation requires accurate feed composition data, which depends on proper sampling to yield reliable analyses.

There’s already expert guidance on the priorities of feed sampling and developing on-farm SOPs (see for example St-Pierre & Weiss).

What about feed analysis priorities related to in-vitro digestibility?

A closer look at the three main in-vitro digestibility analyses — fiber, starch, protein — can support more cost-efficient diet formulation decisions, says Ohio State’s Dr. Benjamin Wenner.

“Fiber is the top analytical priority, especially forage fiber,” Wenner emphasizes, “primarily because of its high proportion in the diet as well as its leading role as a substrate for rumen microbial protein and VFA production.

“Accurate knowledge of the fiber and its digestibility in a diet also relates to the interaction of other components that affect fiber digestibility, such as the effects of minerals on rumen microbial activity.”

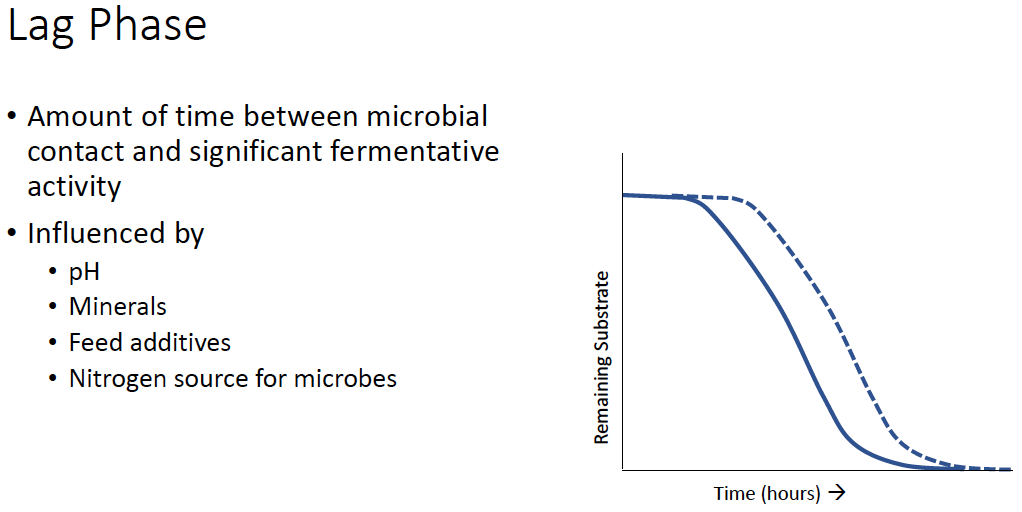

Lag phase per fiber

Illustration of the disappearance (digestion) of substrate with varying lag phase. Microbes take time to adapt to culture

and attach to particles before degradation occurs.

It is critical to account for “lag phase” in feed analysis but less critical for fiber, Wenner says.

Lag phase is the time it takes rumen microbes to attach to feed particles and begin digestion. Standardized sampling technique and lab delivery procedure are important because of requirements for rumen microbes — warmth, oxygen-free status, and stable pH.

Commercial labs excel at fiber analysis, Wenner notes. Nonetheless, variables such as pH control, sugar or starch content, and even mineral composition or other factors can influence results.”

Is 120 hours post-inoculation adequate?” Wenner asks. “Probably 240 hours is technically better for ration models but represents time that many of us don’t have for real-life decisions.”

Starch & protein

Wenner says that lag phase can be a much larger challenge in starch analysis because the assays utilize dry, ground feedstuffs, which do not really represent the form fed to the animal. Further, the lag phase in starch digestibility assays can represent a much larger proportion of the total assay length – typically 7 hours – further impacting results.

Protein digestibility analyses — particularly Ross assays adapted for RUP or RUP-digestibility — may present other challenges. Wenner recalls that researchers have sent the same product to different commercial labs and got back very different results with RUP +/- 5% and RUPd +/- 3-6%. Extrapolating these two could leave nutritionists with total variability ranging 3-12% for estimated digestible RUP fed to the animal.

“The reality of protein analysis,” Wenner says, “is that it represents greater potential for error — errors in sampling, recovery, collection, plus typical analysis variation — which can compound and cascade into less accurate diet formulation.

Analytical budget

“To prioritize your analytical budget,” Wenner says, “focus on fiber analysis — especially for corn silage and haylage. Sample these more frequently because they are the greatest contributor to the total diet, and even consider sampling twice at a time for an average value that would be safer.

“Lastly, because of the variation of conditions between commercial labs, I would recommend using the same lab over time for in-vitro digestibility assays and sending any comparative samples in the same batch.”

Questions?

Email FeedInsight 4U